Before launching Neon Bandits in June of 2015, we spent over 18 months trying to find a factory partner that could produce the highest quality socks. We didn’t want just any socks to have our name on them; we wanted to make a quality sock that met (or exceeded) the durability and functionality of the largest brands in the space. And over the past year and a half, based on the feedback that we have received from customers, teams and partners, we have done just that.

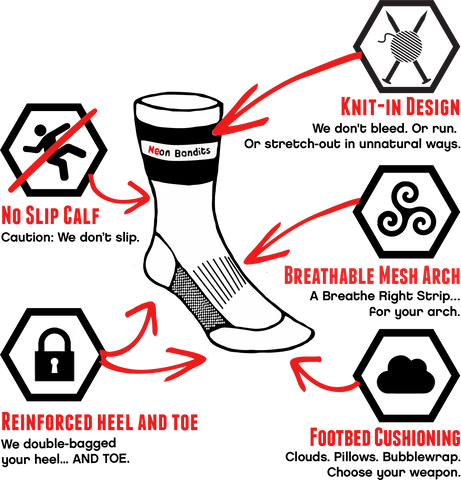

A major point of differentiation (and one that us sock geeks love to boast about) between Neon Bandits and other socks, is that all of our socks feature knit-in design. When we create or develop a new style, or a custom design, we do just that—create and develop. All of our socks are built from the toe up via a process called circle stitching.

Having a sock that is knit-in means that everything from the yarn to the colors of the sock must be extremely well thought-out to translate into a design that is both functional and fun. Our designs compliment the structure of the sock. A couple of big perks of a knit-in sock? Knit-in socks maintain their structure and color—even with extreme wearing and washing.

The drawback? The development timeline of a knit-in sock is a bit more involved than a typical sock timeline, which does mean our lead-times for custom designs can run a little longer. The good news is that we’re always thinking ahead in terms of design and sampling, and continue to prioritize quality and customer satisfaction at the top of our list.

Thinking about a custom sock for your crew would be a great way to kick-off Spring and Summer? Us too!